Epoxy-Mineral Tombstones

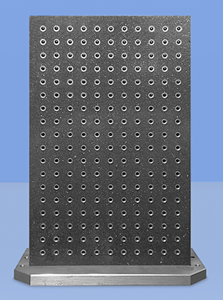

Advanced Machine & Engineering Co. (AME) Rockford, IL now offers its AMROK® brand tombstones in epoxy-mineral material, available in various standard shapes and sizes.

Advanced Machine & Engineering Co. (AME) Rockford, IL now offers its AMROK® brand tombstones in epoxy-mineral material, available in various standard shapes and sizes.

Significant user benefits of this material include vibration damping rated at ten times that of cast iron and 100 times better than aluminum, measured by logarithmic decrement. These tombstones are lightweight, similar to aluminum and offer very stable thermal expansion characteristics, with low coefficient of linear expansion.

The epoxy-mineral material comprises quartz gravel, silica and crushed rock mixed with a high-quality epoxy resin binder. The finished product has a granite-like appearance.

Originally, epoxy-mineral material was used in the machine tool industry to reduce thermal expansion and vibration in machine bases. Today, it’s equally advantageous as a lightweight solution that allows users the ability to utilize the full envelope of the machine.

AME AMROK® epoxy-mineral tombstones are available with either molded steel plugs for tapped holes or ½” inner diameter precision bushings with hardened, threaded inserts on a 2” grid.

About Advanced Machine & Engineering Co.:

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including: spindle interface components, workholding devices, air gaging, and, through their sister company, Hennig, machine enclosures, way covers, . The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our AmSaw® carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S.

For more Information, please visit:

www.ame.com

Or contact:

info@ame.com

Sister company to AME, Hennig, Inc. designs and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities are located in the U.S., Germany, Czech Republic, United Kingdom, Brazil, Mexico, India, Japan, France and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico.

For more information, please visit:

www.hennigworldwide.com